Passivation

The passivation consists in the formation of a relatively inert layer over a material surface (mainly a metal), which hides it against external agents action. Although the reaction between the metal and the external agent is thermodynamically possible at the macroscopic level, the passivizing layer or sheet doesn’t allow that those can interact, in such a way that the chemical or electrochemical reaction is reduced or completely stopped.

It must be distinguished between the passivation and the immunity, where the base metal is itself resistant to the action of corrosive media (noble metals).

On the other hand, the formation of a passivizing layer is not limited to a base metal oxidation. They are also cases where the passivizing layer is formed by reduction.

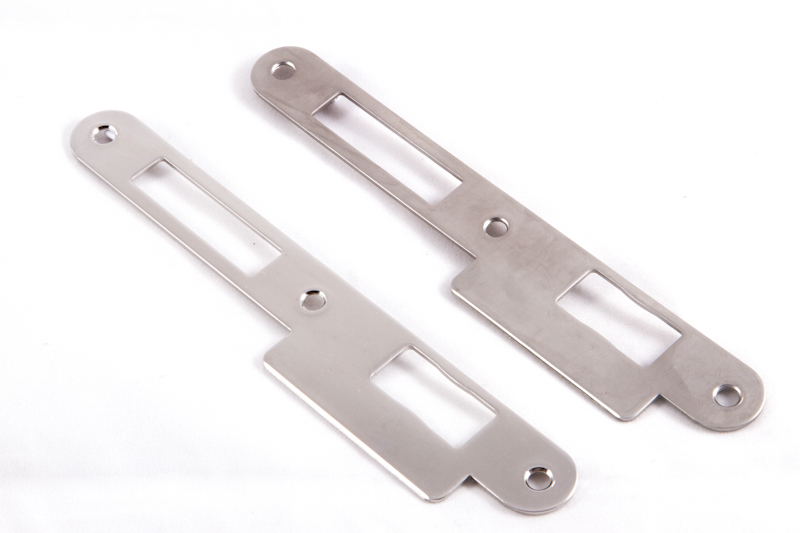

Applications:

This process allows, therefore, strengthen even more the metal rustproof, surface decontamination after welding, sanding or machining.

Recently, we have adapted our installations to do this process on large pieces, in order to deal with an increasing demand in sectors like rail and/or boilermaking in general.